Description

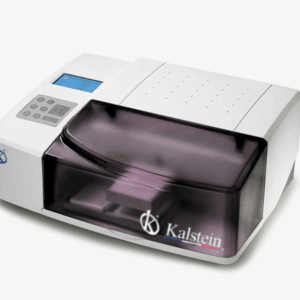

The Microplate Washer YR06088 is an advanced, microprocessor-controlled machine designed for executing user-defined washing protocols with precision. This microplate washer is versatile, capable of washing flat, U, and V-bottom strips and plates, making it a staple in laboratories requiring efficient cleaning solutions. Its sophisticated manifold design, featuring two needles for aspiration and dispensation, effectively minimizes cross-contamination risks. Additionally, the device includes a liquid level detection and alert function for added convenience and safety.

Market Price

The Microplate Washer YR06088 is positioned as a high-value laboratory tool, with market prices for similar microplate washers ranging between $2,350 and $3,100. This pricing reflects the advanced features and durability of such devices, making them an essential investment for laboratories focusing on reliable and efficient washing processes.

Frequently Asked Questions

What types of plates can the Microplate Washer YR06088 accommodate? The washer can handle 96 or 48 well plates with round, flat, or V-shaped bottoms.

Does the microplate washer include any alert functions? Yes, it features an alarm for indicating the lack of washing liquids, ensuring uninterrupted operations.

What are the available head options? The device includes both 8 and 12 channel heads to facilitate diverse washing volumes and protocols.

Advantages and Disadvantages

One of the primary advantages of the Microplate Washer YR06088 is its capability to store up to 50 washing protocols, each allowing up to 99 washing cycles, which significantly enhances operational efficiency. The small residual volume of less than 3 μl ensures thorough plate washing with minimal waste. However, a potential downside is the device’s reliance on an RS232 port, which may require additional adapters for integration with modern systems.

Product Use in Practice

In a laboratory setting, the Microplate Washer YR06088 simplifies and accelerates the washing processes of microplates used in various assays and experiments. It ensures consistency and reliability in multiple washing protocols, critical for maintaining the accuracy of scientific results.

Recommendations

To maximize the lifespan and performance of your Microplate Washer YR06088, regular maintenance, including routine checks of the liquid levels and inspection of the aspiration and dispensation needles, is recommended. Consider leveraging the benefits of the memory function to customize and optimize washing protocols for different experimental needs.

Features

- Washes flat, U, and V-bottom strips and plates with small residual volume.

- Equipped with a dual-needle manifold to prevent cross-contamination.

- Features alert functions for liquid levels and includes two 2-liter bottles.

- Supports both 8 and 12 channel head configurations for varied washing volumes.

- RS232 connectivity for integration into laboratory data systems.

Technical Specifications

| Model | YR06088 |

| Washing | 96 or 48 well plates with round, flat or V-shaped bottoms. |

| Includes head | 8 and 12 channel. |

| Washing volume: | 50-3000 ml with 8 channel head, 50-2000 ml with the 12 channel head. |

| Drying time: | 0 to 24 hours. |

| Memory: | 50 washing protocols with up to 99 washing cycles in each. |

| Residual volume: | <3 ul. |

| Includes | Two 2 liter bottles, for washing liquid and for waste. |

| Alarm | For lack of washing liquids. |

| Port | RS232. |

| Dimensions: | 39x33x18 cm. Weight: 9 kg. |